Yakakosha conductivity Yakakwirira chiratidzo chekufambisa mutsara Alloy enamelled kutenderera waya Yakakwirira mechanical zvivakwa zvinogona kugadzirwa

Chii chinonzi alloy wire

1.1 Kuti uvandudze kushanda kwakakosha kweamelled waya, alloy wire inonzi enamelled wire iyo conductor inogadzirwa nemhangura alloy. Alloy wire ine yakakosha magetsi conductivity, mechanical zvivakwa, kuneta kuramba uye yakanakisa kukotama kuramba. Kuti isangane nezvinodiwa zvekushandisa zvevatengi, kambani yedu inopa akasiyana alloy enamelled waya. Kuti tisimbise humwe hunhu hwewaya, isu tichaenderera mberi nekugadzirisa waya alloy kusangana nezvinodiwa zvevatengi.

1.2. Tinogona kupa mhangura sirivheri alloy, mhangura tin alloy, mhangura nickel alloy, sirivheri plating, nickel plating uye mamwe alloy enamelled waya, pamwe alloy conductors maererano akasiyana mafomu.

Rudzi rwe alloy enamelled wire

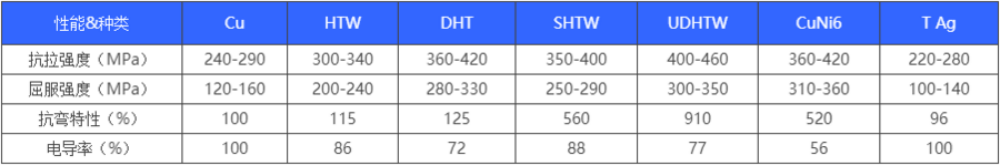

2.1 High tension waya maitiro (HTW, DHT, SHTW, UDHTW):

Iyo yakakwira tension waya ndeye copper alloy self-adhesive enamelled waya yakanyatso kugadzirirwa zvinodiwa zvekushandisa zvemhando yepamusoro michina. Mienzaniso yayo inonzi HTW, DHT, SHTW, UDHTW; Inoshandiswa mumashandisirwo ane zvakakwirira zvinodikanwa zvekukotama kuramba uye kuvimbika. High tension wire ine yakakwirira tension resistance, kuvimbika, conductivity uye kukotama kuramba pane enamelled copper waya.

chimiro:

·Kusimba kwesimba ndeye 20-90% yakakwirira kudarika iyo enamelled yemhangura waya, inokodzera mhepo inomhanya-mhanya, uye gumbo rekutengesa harisi nyore kuputsa.

·Conductivity>77%.

·Basic insulating layer, self-adhesive layer uye enamelled copper wire zvakafanana.

·Kuitwa kweyekunakisa welding kwakafanana nekweyamelled yemhangura waya.

2.2 Yakakwira impedance alloy waya maitiro (CuNi6):

Iyo yakakwira impedance alloy waya imhangura alloy enamelled waya yakanyatso kugadzirirwa yakakosha impedance application zvinodiwa, uye modhi yayo inonzi CuNi6;

chimiro:

·Kukosha kwe impedance pamamita 6-8 nguva dzeyemhangura enamelled waya, iyo inokodzera jenareta kana yakakosha coil inoshandiswa kugadzirisa kukosha kweQ.

·Basic insulating layer, self-adhesive layer uye enamelled copper wire zvakafanana.

·Kuitwa kweyekunakisa welding kwakafanana nekweyamelled yemhangura waya.

·Akanakisa masaini kutapurirana maitiro.

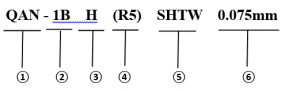

2.3 Chigadzirwa kodhi tsananguro:

1. Rudzi kodhi ye insulating layer

AN=Weldable UEW

ZN=isingabatike PEW

XYN=EIW isingabatike

2. Paint firimu ukobvu (1,2,3, kureva IEC uye vatengi mitemo).

3. Insulation tembiricha kuramba giredhi

F=155

H=Kirasi 180

S * inomirira tembiricha yekudziya yakaderera

4. Rudzi rwe-self-adhesive layer (R self-adhesive layer second softening tembiricha ≤ 130 ℃, R5 self-adhesive layer second softening tembiricha ≤ 160 ℃, R7 self-adhesive layer second softening tembiricha ≤ 190 ℃, C self-adhesive layer idoro rinopisa mhepo mbiri-kushandisa, SV yekuzvinamira layer inoomesa kupisa).

5. Alloy category

HTW=Waya yakajairika

DHT=Waya ine tension yakakwirira

SHTW=waya yepamusoro-soro

UDHTW=waya yakawedzera tension

6. Zita dhayamita ye conductor (mm).

Chigadzirwa mhando: Φ 0.030-0.15mm (AWG52-34)

.jpg)

-300x300.jpg)

2-300x300.jpg)

1-300x300.jpg)

1-300x300.jpg)