Tembiricha uye kumanikidza kuramba kuvandudza kushanda kwekushanda F-kirasi 1UEW enamelled self-adhesive coil indasitiri yemagetsi kurapwa.

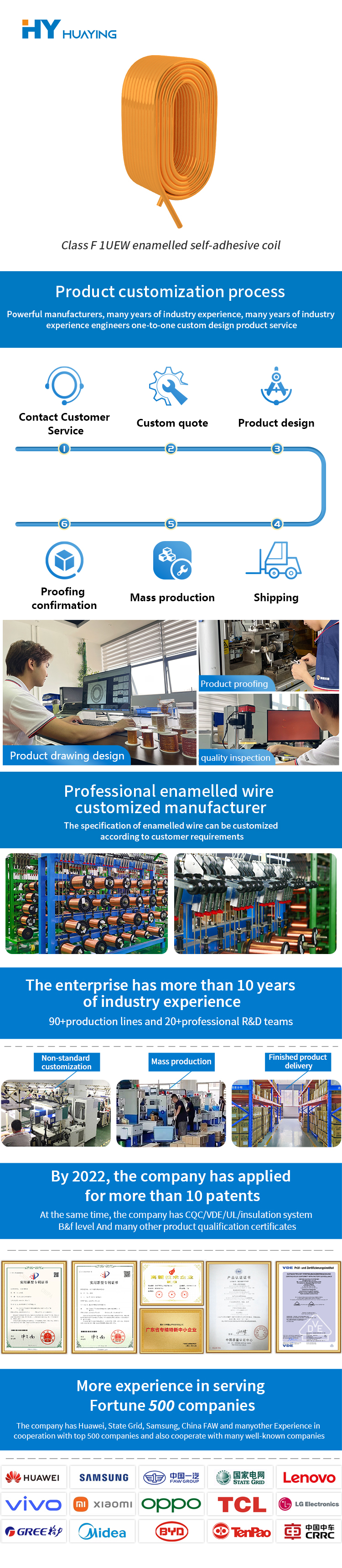

Zita rechigadzirwa: F-kirasi 1UEW enamelled self-adhesive coil

Zita rechigadzirwa: F-kirasi 1UEW enamelled self-adhesive coil

·Self-adhesive enameled wire (self-adhesive wire), inozivikanwawo se self-melting wire, ine imwe yakawedzera yependi yekuzvinamira pamusoro peiyo enameled waya.

·Zvakanyanya kuoma kugadzira iyo yakaoma-yakaumbwa isina furemu coils inoshandiswa mukutanga maTV uye mamwe madiki mota ane akajairwa enameled waya. Iyo nzira yekugadzira yerudzi urwu rwearature coil ine yakasarudzika. Kutanga, mhepo imwe chete inofanirwa kugadziriswa uye kuumbwa, uye ipapo imwe neimwe yakaumbwa mhepo inoumbwa kuita mhepo inotenderera. Iyo imwe chete inomonereka yekugadzira nzira yaishandiswa kuve yekuisa adhesive pamusoro pekunze kwewaya enameled kuigadzirisa pane mold, uye wozoibika nekuigadzira. Iyo motor winding forming process yakawana yakanaka kwazvo mhedzisiro yehupfumi. Inoshandiswa zvakanyanya muzvikamu zvakakosha zvezvigadzirwa zvemagetsi senge coreless motors, self-adhesive coils, micro-motor, electronic transformers, sensors, uye zvemagetsi zvikamu. Kusimudzirwa kwezvombo uye transformer armature.

Bonding process:

Iyo yekuzvinamira layer yakavharwa pamusoro peiyo yekuzvinamira waya inogona kuburitsa kunamatira kuburikidza nekuita kwekupisa kwakanyanya kana makemikari zvinonyungudutsa.

Kupisa kwepamusoro / kupisa kusungirirwa:

Yese Elektrisola self-adhesive layers inogona kusungwa nekudziya. Iyo waya inogona kupiswa yakananga nemhepo inopisa panguva yekutenderera kwemhepo, kana ronda coil rinogona kupisa kuburikidza nechoto, kana ikozvino inogona kuiswa kune coil mushure mekupedzwa kwemhepo. Nheyo yenzira dzese idzi ndeyekupisa coil inomonereka kune tembiricha zvishoma pamusoro pekunyunguduka kweiyo-self-adhesive layer, kuitira kuti self-adhesive layer inyunguduke uye inobatanidza waya pamwe chete. Mhepo-kuburikidza nechisungo chine mukana wekusada yechipiri bonding process mushure memhepo. Iyi nzira inodhura-inoshanda uye inonyanya kushandiswa kune self-adhesive waya dzine zviyero zviduku kudarika 0.200mm. Iyi nzira yakave yakakurumbira mumakore mashoma apfuura nekuvandudzwa kwemhando yepamusoro-yepamusoro-yepamusoro-yega-adhesive layer types.

Oven Bonding:

Kusunga kwevheni kunoitwa nekupisa coil yeronda. Iyo coil ichiri kuchengetwa pachigadziriso kana chishandiso panguva yemhepo, uye iyo coil yese inopisa zvakaenzana muchoto pane yakakodzera tembiricha uye nguva yakakwana, yobva yatonhodzwa. Nguva yekupisa inoenderana nehukuru hwecoil, kazhinji maminitsi gumi kusvika makumi matatu. Zvakaipa zvehovhoni bonding inguva refu yekuzvibatanidza, mamwe matanho ekuita, uye zvingangonyanya kudiwa pahuwandu hwewaya-maronda ekushandisa.

Electrobonding:

Izvi zvinoitwa nekuisa magetsi kune yakapedzwa coil uye kugadzira kupisa kuburikidza nekupikisa kwayo kuti iwane tembiricha yakakodzera yekubatanidza. Iyo voltage uye nguva yesimba inotsamira pakukura kwewaya uye dhizaini yecoil uye nekudaro inoda kuvandudzwa kune yega yega application. Iyi nzira ine zvakanakira kukurumidza kukurumidza uye yunifomu kupisa kugovera. Kazhinji akakodzera self-adhesive waya newaya dhayamita saizi yakakura kupfuura 0.200mm.

Solvent bonding:

Mamwe anozvinamira akaturikidzana anogona kuvhurwa uchishandisa chaiwo zvinonyungudutsa panguva yekumonera coil. Kana mhepo ichimonereka, yakanyungudika-yakanyoroveswa inonzwa ("wet winding") inowanzo shandiswa kupfavisa self-adhesive layer. Kuita uku kunoda kushandiswa kwechishandiso kubata makoiri panzvimbo, uye makoiri anobatanidzwa pamwechete mushure mekunge solvent yaoma. Iyo coil inofanira kubva yadziiswa muovheni kuti imwe denderedzwa inyungudise zvakasara zvinonyungudutsa uye kupedzisa iyo yekuzvinamira dhizaini yekurapa maitiro ekuti optimum bond simba. Kana paine chinonyungudutsa chiri mukoiri, chinogona kukonzera kuti koiri ikundikane mushure menguva refu.

1-300x300.jpg)